Image provided by wabtec.com

Wabtech Corporation Logo

February 1, 2013

Napier becomes a Wabtec Corporation company

"Napier Turbochargers is renowned as an innovative company with an excellent suite of products delivering high performance. I am delighted the business has been acquired by a Company committed to investing further in R&D to maintain its technology and in the development of the business to meet our customer demands."

Andy Thacker, Managing Director, Napier Turbochargers

2010

Future-proofed turbochargers

At the Worldwide Turbocharger Conference in Hamburg, Germany, industry experts gathered to discuss how to 'future proof' today's turbochargers against tomorrow's emissions and safety legislations. Commercial director, Napier Commercial Director, served on the Conference Advisory Panel and highlighted our range of next-generation turbochargers, genuine spare parts and worldwide service centres.

2008

Further growth and success

Increasing our Lincoln manufacturing facility footprint by 20% allowed us to incorporate a new turbocharger assembly production facility, and to relocate and expand the turbocharger overhaul facility; all signifying Napier's ongoing commitment to continually improving business performance.

2009

Making a splash in shipbuilding

In September, Napier Turbochargers exhibited at the SMM Show in Hamburg: the largest marine shipbuilding exhibition in the world and probably the most important event in Napier's calendar. The show as a big success resulting in a number of potential new customers (including a three-year contract with a major ferry operator), service contracts and spare parts orders.

June, 2008

Going our own way

In June, Napier Turbochargers gained independence from former owner Siemens Power Generation following a management buyout headed by the Managing Director. Napier continued as a primary supplier of turbochargers for the marine, power and rail industries.

image provided by www.napier-turbochargers.com

Napier Turbochargers Trademark Logo

Napier 7 Series Turbocharger

1998

Introducing the 7 Series

The new 7 Series represented a fundamental shift in turbocharger performance and reliability. The innovative layout and bearing design allows these units to combine market-leading pressure ratio and efficiency levels with excellent reliability.

1961

Napier aero-engine business transferred to Rolls-Royce

The new company continued to market the Gazelle but dropped the Eland. Today, Napier Turbochargers is no longer in the engine business: when Deltic sales ended in the 1960s the company had no new modern designs to offer.

1948 — 1954

Jet engine design

Along with every other engine company in the post-war era, Napier turned to jet engine designs. Deciding to attack the only market not yet wrapped up by the larger vendors, Napier began the design of a number of turboprop designs which saw some use, notably in helicopters: the Gazelle in particular went into several models of the popular Westland Wessex helicopter.

1947

Napier Lion

Land Speed Record - 394.196 mph

image provided by Geni | wikimedia

The photo shows the Napier-Railton Mobil Special race car on display at the Thinktank museum in Birmingham with the shell raised above the rest of the car.

1946

Post war marine engines

Napier was asked by the Royal Navy to supply a diesel engine for use in patrol boats, but the Culverin engine's 720hp (537kW) was not nearly enough for their needs. So Napier designed the Deltic: three Culverins arranged in a large triangle. Considered one of the most complex engine designs of its day, the Deltic proved very reliable and as well as being used in torpedo boats, minesweepers and small naval vessels, went into service after the war as a locomotive powerplant (in British Rail's Class 55).

1948

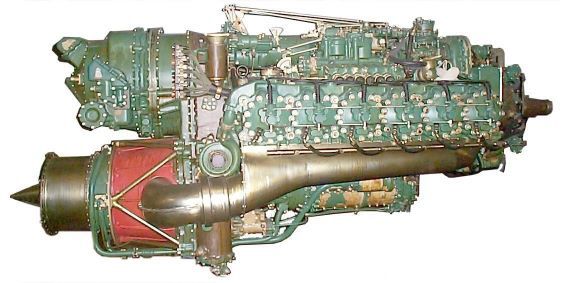

Napier Nomad Aero-engine

The last of the great Napier engines, the Nomad was a 'turbo-compound' design that combined a diesel engine with a turbine to recover energy otherwise lost in the exhaust. This resulted in the best specific fuel consumption of any aircraft engine, even to this day. However, as even better fuel economy could be had by flying a normal jet engine at much higher altitudes, the Nomad was largely ignored by the market and duly cancelled.

image provided by Kimble D. McCutcheon

Nomad Turbo-Compound Aero-engine

1943

Napier Sabre V

The Sabre V delivered 2,400 horsepower (1,800 kW) consistently and the reputation of the engine started to improve. This version of the Sabre was the last to enter service, being used in the Hawker Typhoon and its derivative plane, the Hawker Tempest.

image provided by wikimedia.org

Hawker Tempest I

1939

Napier Lion

Land Speed Record - 369.74 mph

1933

Napier Culverin diesel aircraft engine

Source: Wikipedia, the free encyclopedia

The Napier Culverin was a licensed built version of the Junkers Jumo 204 six-cylinder vertically opposed liquid-cooled diesel aircraft engine built by D.Napier & Son. The name is derived from the French word, culverin, for an early cannon or musket. First flown in 1938 using a Blackburn Iris V biplane flying-boat aircraft, the engine went into production for use in the Fairey III biplane.

1933

Napier Lion

Air Long Distance Record - 5,309 miles

1932

Napier Lion

Land Speed Record - 253.968 mph

1931

Napier Lion

Land Speed Record - 246.1 mph

image provided by wikimedia.org

Campbell-Napier-Railton Blue Bird

1929

Napier Lion

Land Speed Record - 231.4 mph

image provided by Andy Dingley

Golden Arrow Land Speed Racer

1937

Napier 24-cylinder Sabre engine

Source: Wikipedia, the free encyclopedia

The Napier Sabre was a British H-24-cylinder, liquid cooled, sleeve valve, piston aero engine, designed by Major Frank Halford and built by D.Napier & Son during World War II. The engine evolved to become one of the most powerful inline piston aircraft engines in the world developing from 2,200 horsepower (1,640 kW) in its earlier versions to 3,500 hp (2,600 kW) in late-model prototypes.

image provided by Andy Lloyd | Napier Power Heritage Trust

12 Cylinder "Lion" Engine at Flying Legends 2013

1932

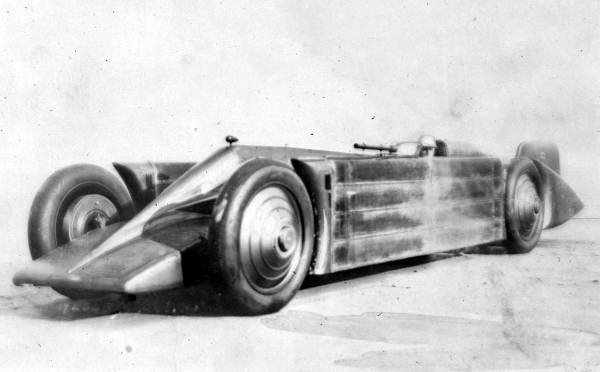

Napier-Railton aero-engine race car

Source: Wikipedia, the free encyclopedia

The Napier-Railton is an aero-engined race car built in 1932, designed by Reid Railton to a commission by John Cobb, and built by Thomson & Taylor. It was driven by Cobb, mainly at Brooklands race track where it holds the all-time lap record (143.44 mph (230.84 km/h)) which was set in 1935 and now stands in perpetuity since the track fell into disuse during the Second World War.

1932

Napier Lion

Water Speed Record - 112 mph

1929

Napier Lion

Air Speed Record - 336.3 mph

image provided by Andy Dingley

Gloster VI Racing Seaplane

1927

Napier-Campbell Bluebird

image provided by wikimedia.org

Sir Malcolm Campbell in the famous "Bluebird" powered by the W12-block Napier Lion Engine

1918 - 1924

Continued vehicle production

During this period, Napier provided 2,000 trucks and ambulances to the War Office. In 1919, civilian car production recommenced with a 6-litre six-cylinder car, the T75. It cost about the same as a Rolls-Royce Silver Ghost and in the early 1920s sales declined, with the last cars made in 1924. An attempt was made to buy the bankrupt Bentley company in 1931 but Napier was outbid at the last minute by Rolls-Royce. The company's last vehicle project was a three-wheeled tractor-trailer goods vehicle, which Napier sold to Scammell.

1915

First World War aero engines

Early in the First World War, Napier was contracted to build engines from other companies' designs: initially a V12 Royal Aircraft Factory model and then Sunbeam Arabs. Both proved to be rather unreliable and in 1916 Napier decided to design their own instead, an effort that led to the superb W-block 12-cylinder Lion.

1912

Car Production

In 1912, Napier bought Edge's distribution and sales company, and production rose to around 700 cars a year with many supplied to the London taxi trade. That year, only six models were produced.

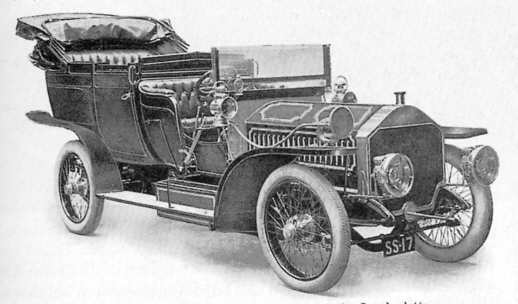

image provided by Malcolma | en.wikipedia

Napier Type 37 60hp car

1902

The first British winner of an international motor race

In 1902 S. F. Edge drove a specially constructed 6,436 cc 4-cylinder Type D50 2-seater racing car in the Gordon Bennett trophy race between Paris and Innsbruck, winning the race.

1918

Napier Lion

Height Record - 30,500 feet

1916 - 1926

12-cylinder Lion engine

This famous Napier product became a revolutionary aero engine; maybe the most widely used and successful ever built. It powered more than 160 types of aircraft worldwide and continued to set world records in the air, on land and on water.

1903

Expanding into marine engines and launches

In 1903 S.F. Edge's Napier launch won the inaugural British International Harmsworth Trophy for speedboats at Cork Harbour in Ireland, driven by Dorothy Levitt. She achieved 19.3 mph (31.1 km/h) in a 40-foot (12 m) steel-hulled, speedboat fitted with a three-blade propeller.

Dorothy Levitt driving the Napier motor yacht

1899

The first Montague Napier car

Montague Napier at the Lambeth works finished the first 8hp car five days before the start of the 1900 Thousand Mile Trial in April. This car not surprisingly had teething troubles but after overcoming some problems had the power and reliability to complete the 1000 miles winning its class. A remarkable achievement with their first car.

1839 - 1859

Early Production

Between 1840 and 1860, Napier prospered, with a well-outfitted factory and between 200 and 300 workers. The company made a wide variety of products, including a centrifuge for sugar manufacturing, lathes and drills, ammunition-making equipment for the Royal Arsenal, Woolwich and railway cranes.

1895

Montague Napier

Montague Napier, born in 1870, purchased the York Road business when his father died. When Montague met Selwyn Francis Edge, then a manager at the Dunlop Tyre Company, he persuaded Napier to improve his Panhard vehicle, converting to wheel steering from tiller and improving the oiling.

Still dissatisfied, Napier decided to fit an engine of his own design: an 8hp vertical twin with electric ignition. Edge was impressed and encouraged Napier to make his own car. With his former Dunlop boss Harvey du Cros, Edge formed the Motor Power Company and agreed to buy Napier's entire output. The first of an initial order of six was delivered on 31 March 1900.

1866 - 1894

James Napier

Born in 1823, James Napier joined the firm in 1837. It was renamed D. Napier & Son in 1847 and he became head of the firm in 1867. He specialised in beautifully crafted precision machinery for making coins and printing stamps and banknotes although an excellent and intentive engineer, he was a poor businessman in his later years. By 1895 James had as few as seven employees and the York Road business was in a run-down state by the time of his death.

image provided by napierheritage.org.uk

Bank Note Printing Machine

1808

In the beginning

Napier was founded in 1808 by David Napier, specialising initially in precision printing machinery and progressing to bullet machines, hydraulic presses for Brunel, and precision coin machines for the Royal and European Mints. In 1824, David's own design 'Nay-Peer' cylinder press was made famous by T.C.Hansard, printers of the official record of Parliament. In 1833, Napier constructed a machine for making compressed musket and rifle balls, improving the accuracy of small arms fire. The company won medals at the Great Exhibition in 1851 and 1861.